Artificial cellulose fibres such as viscose, are fibres made from plant-derived cellulose materials (namely wood). They are chemically transformed with the help of solvents, for example, in order to give them characteristics similar to those of natural fibres but at a low cost.

Key data

Type of fibre : artificial chemical fibre

Global annual production:approximately 5.2 million tonnes

Main producer countries : China, India, Indonesia

Place in world fibre production: : 3rdequating to almost 5% of global production

Source : Preferred Fiber & Materials Market Report 2022 - Textile Exchange

Properties of the fibre and application examples

Viscose is sometimes referred to as artificial silk given that it was originally invented to replace silk and obtain a less-costly, glossy finish. In addition, these properties are close to those of cotton given that it is composed of cellulose : Glossy - Silky to touch - Resistant - Breathability.

Viscose is used in :

- lingerie for the glossiness and silky touch.

- linings for the glossiness, silky touch and breathability properties.

Can viscose be recycled ? Yes, products composed of viscose can be mechanically (cutting, tearing, garnetting) or chemically (enzymatic dissolution) recycled..

Source : Les fibres chimiques et artificielles - Environnement et savoir

Environmental impacts of production

Harmful chemical products

Use of harmful chemicals during the production process which are sometimes discharged into the surrounding waterways with a devastating impact on the biodiversity and health of the population.

Water consumption

Between 420 to 750 liters of water are needed to produce 1 kg of viscose fibre.

Massive deforestation

Every year 150 million trees are felled for the wood pulp needed to manufacture viscose.

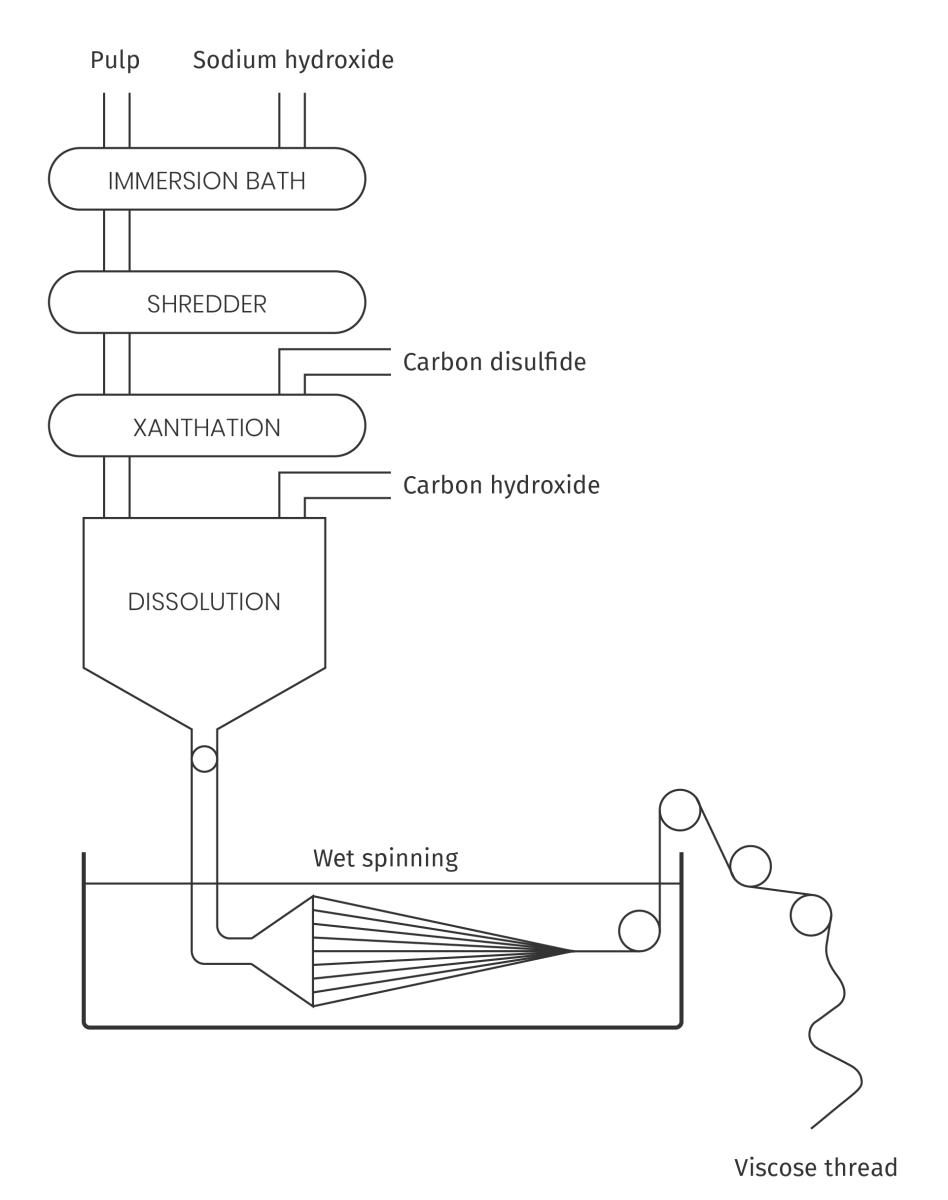

The raw material used to create viscose is wood pulp. To transform it into thread:

- The wood is first cut and crushed to obtain a pulp.

- The pulp is soaked, shredded then treated with chemicals.

- It is then chemically dissolved in caustic soda and treated with sodium hydroxide and carbon disulfide.

- The pulp is then placed in a bath of sulfuric acid in order to dissolve and solidify it, then extruded into filaments through dies.

- The filaments are stretched to obtain thread.

Disclamer : As in all eco-design approaches, before choosing a material, it is essential to analyze the environmental impact of the entire life cycle of a product and to compare different scenarios in order to identify which one is the most beneficial for the environment.

There is no ideal material, it is necessary to choose a material according to the environmental attributes that we want to give in our product.

RECYCLED CELLULOSic ARTIFICIAL FIBer

From used textiles made from viscose or other artificial cellulose fibres, it is possible to recycle material and transform it into a thread using a chemical recycling process. Materials undergo enzymatic dissolution.

This treatment modifies the structure of the fiber to dissolve it in a solvent and render it spinnable.

The filament can consequently undergo a classic spinning process after being extruded via dies.

In addition to being used to recreate thread, artificial cellulose fibres have numerous outlets: household or professional cleaning cloths, transformation into unwoven fabric, into flock or fuel.

Example of textile manufacturers using chemical recycling to create new manmade cellulosic fiber : NuCycl™ by Evrnu, Refibra™ by Lenzing, Circulose® by Renewcell, Infinna™ by Infinited fibers and FINEX™by Sateri

LYOCELL, Modal and eco vero

These materials are very close alternatives to viscose, but with a manufacturing process that tends to be more environmentally friendly.

All three, in the same way as viscose, are manmade cellulosic fibers obtained from wood pulp.

The manufacturing process of Lyocell is recognized as having less impact on the environment. Indeed, the solvent in which the wood pulp is dissolved is recovered at 99%, purified and then reintegrated into the manufacturing process in a "closed circuit". It is also non-toxic and non-corrosive. Moreover, the use of eucalyptus wood allows a sustainable management of forests since this tree has a fast growth cycle (7 years). The manufacture of Lyocell requires very little water (less than 1000 liters of water for 1kg of Lyocell against more than 5000 liters of water to produce 1kg of cotton).

Modal is also manufactured in a "closed circuit", which means that water and chemicals are reused and recycled in the manufacturing process until they are exhausted, and wastewater is also treated before being discharged. In the absence of a closed circuit, the chemicals used are dangerous for health and the surrounding biodiversity. Also be careful that the beech wood used in its manufacture is from sustainably managed forests.

The Ecovero™ produced by the company Lenzing™ is made of wood from sustainably managed forests, certified FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). The manufacturing process generates approximately 50% less CO2 emissions and water consumption compared to conventional viscose.

Source : Fiber production - Lenzing

Alternative Fibers

To produce a manmade cellulosic fiber, it is also possible to use other resources than wood. Bamboo fiber, cotton linter (a part initially discarded), algae, or even agricultural waste! These raw materials have the advantage of being sustainably grown, renewable or anti-waste.

On the other hand, the production processes remain the same as for viscose, using dangerous chemicals and requiring a lot of water. It is therefore important that the production is done in closed circuit.

Examples of textile manufacturers using resources other than wood to create new artificial materials :

Cupro-bemberg, AGRILOSE, SPINNOVA®