Leather is an animal skin having undergone a complex transformation process, namely via tanning, in order to make it rot proof. Materials which are not made from animal skin can therefore not be referred to as leather.

Key data

Nature of the fabric: : tanned animal skin

Global annual production : approximately 7 million megatonnes

Main producer countries :China, Italy, Vietnam (per order of production)

Source : Preferred Fiber & Materials Market Report 2022 - Textile Exchange

Properties of leather and application examples

The properties of leather vary according to the origin of the skin, the type of tanning employed and the finishings applied. Nevertheless, leather can have the following properties: Resistance - Suppleness - Thickness - Breathability.

Leather is used in:

-

furnishings owing to its resistance.

-

footwear for its resistance and breathability.

Can leather be recycled? Numerous projects are in progress to succeed in recycling leather. Nevertheless, for the moment, no veritable industrial solutions exist.

ENVIRONMENTAL WATCH POINTS

Animal well-being

Pay attention to the origin of skin; animal welfare standards vary according to geographical zone.

Pollution of soils, water and air

Owing to the chemical products used for tanning.

Health risks

Pay attention to production and working conditions.

Significant water consumption

Pay attention to geographical origin as water management regulations vary.

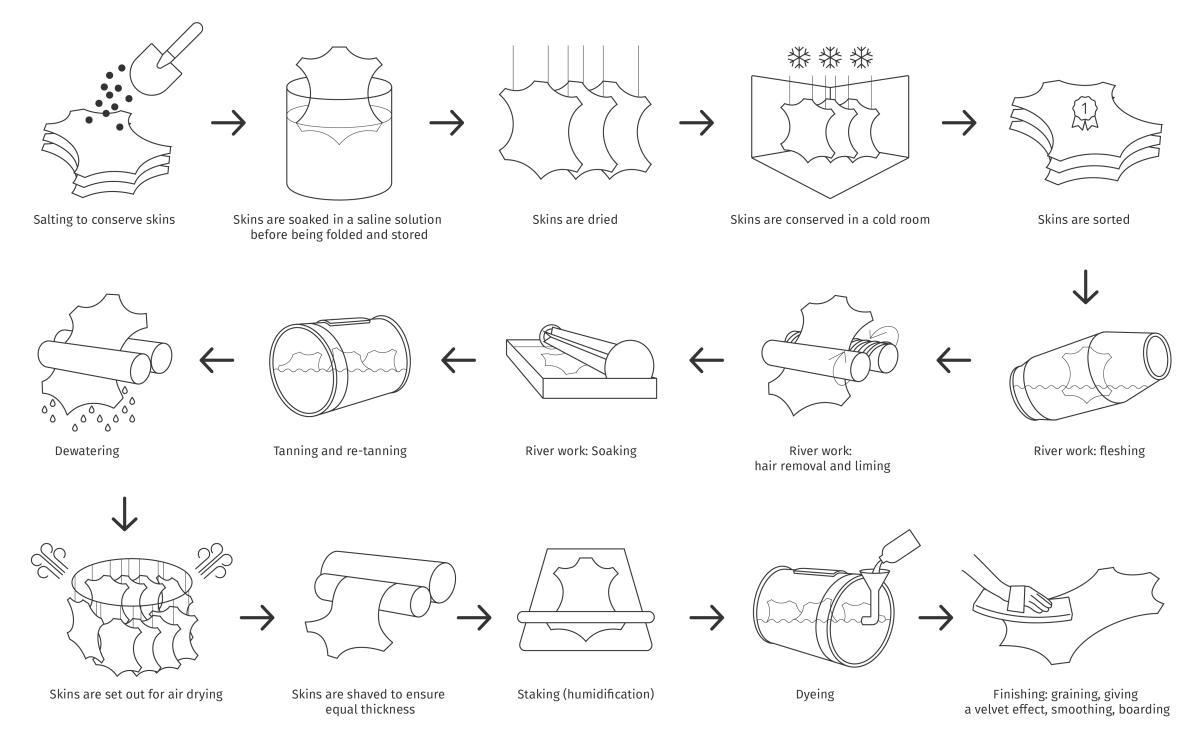

Numerous stages are necessary to transform skin to leather

- Preservation of the skin (namely via salting).

- River work" to eliminate the epidermis, hair and fatty tissues as well as to clean the skins.

- Skins are sorted according to species / races, weight and quality.

- Tanning to transform the skin into leather thanks to tannins which are plant, mineral or combined substances used to transform putrescible skins into a rot-proof material, leather.

- Wrought ironing / Finishing : to transform tanned leather into finished leather, ready to be used

Source : Dossier Découverte Qu'est-ce que le cuir ? - Conseil National du Cuir

LEATHER PRODUCTION DIAGRAM

Disclamer : As in all eco-design approaches, before choosing a material, it is essential to analyze the environmental impact of the entire life cycle of a product and to compare different scenarios in order to identify which one is the most beneficial for the environment.

There is no ideal material, it is necessary to choose a material according to the environmental attributes that we want to give in our product.

PLANT TANNING

Generally speaking, leather is tanned (transformation of skin into leather) thanks to mineral tannins, namely chrome. Nevertheless, other tanning processes exist such as plant tanning which is the oldest method. This process consists in using plant tannins, extracts of leaves or bark, to transform the skin into leather.

Plant tanning is complementary to mineral tanning. In effect, the finish of the material, both visually and when touched, can differ according to the type of tanning used.

Beware of the term "plant" however; this term does not mean that the environmental impact of the material is lower.Indeed, this method cannot be qualified as natural, because it often requires the use of chemical products, especially for fixing the pigments. This process of tanning takes more time, the treatment of a skin will last at least 48 hours and can go up to several months against 1 day for the "conventional" method.

"ALTERNATIVE" MATERIALS TO LEATHER

By definition, leather is an animal material. Indeed, since 2010, in France, the term "leather" is registered and its use is regulated by a decree. The mentions "imitation leather", "fake leather" or "imitation leather" to describe a product are strictly prohibited. All materials called "vegan" leather are therefore false. These materials are presented as alternatives to leather, beware, today there is no certainty on their durability, there is no reason to compare their characteristics to those of leather. It is advisable to be vigilant in the choice of materials.

The most common material to replace real leather is "synthetic leather", this material is made of plastic in the form of PVC or PU. It can imitate very well the different aspects of leather and is available in many colors and textures. It is important to remain vigilant about the durability of "synthetic leather".

Besides that, new materials of plant origin are emerging, including from mushroom, cork, hemp, pineapple, eucalyptus, apple...

Among these materials, it is frequently the "by-products" that are used in the manufacture: the skin of the apple, the pineapple leaves or the residues of hemp fiber.

These manufacturing processes use a raw material that is basically a waste product of the food industry (like leather) or agriculture, the use of the plant product is therefore optimized.

Although these materials are of vegetable origin, it is noted that they frequently use binders of petroleum origin.

Source : Preferred Fiber & Materials Market Report 2022 - Textile Exchange

LEATHER-BASED RECYCLED MATERIALS

Leather-based recycled materials also exist, namely from tannery waste and production off-cuts. Examples:

- ELeather, an English company, which produces a material from tannery shavings /waste (tanned using chrome) to bind them (hydroentanglement) with an unwoven textile core. The material is then coated with polyurethane.Bonded leather, a material obtained from tannery shavings /waste (plant tanning) which is shredded and mixed with 40/50% of latex.

To find out more about leather-based recycled materials, consult the report: Recycled Leather - A primer for industrials to better understand alternative materials to virgin leather