Polyester is a synthetic, petroleum-based fibre. The most common polyester is PET (Polyethylene Terephthalate), which is the result of the polymerisation of ethylene glycol and terephthalic acid monomers. The plastic polymer is melted and extruded through dies in order to give it a continuous filament structure, consequently enabling the creation of a thread.

Key data

Type of fibre : synthetic chemical fibre

Global annual production : approximately 50 million tonnes

Main producer countries : China, India, ASEAN (per order of production)

Place in world fibre production: 1st place, equating to almost 50% of global production

Source : Preferred Fiber & Materials Market Report 2022 - Textile Exchange

Properties of the fibre and application examples

The properties of polyester fibre are : Crease-resistance - High resistance to traction and abrasion - High UV resistance - Good elasticity - Breathability.

Polyester is used in :

- Shirts for easy care, crease-resistant.

- Sports clothing for breathability and elasticity.

Can polyester be recycled? Yes, products composed of polyester can be mechanically (tearing, shredding, garnetting, melting) or chemically (chemical dissolution) recycled.

ENVIRONMENTAL IMPACTS OF PRODUCTION

It's a non renewable source

Polyester is an oil derivative that takes millions of years to form. 1.5kg of oil is necessary to manufacture 1kg of polyester.

High energy consumption

1kg of polyester uses twice as much energy during the production stage as 1kg of cotton.

High greenhouse gas emissions

The process used to transform oil into polyester fibre provokes high greenhouse gas emissions.

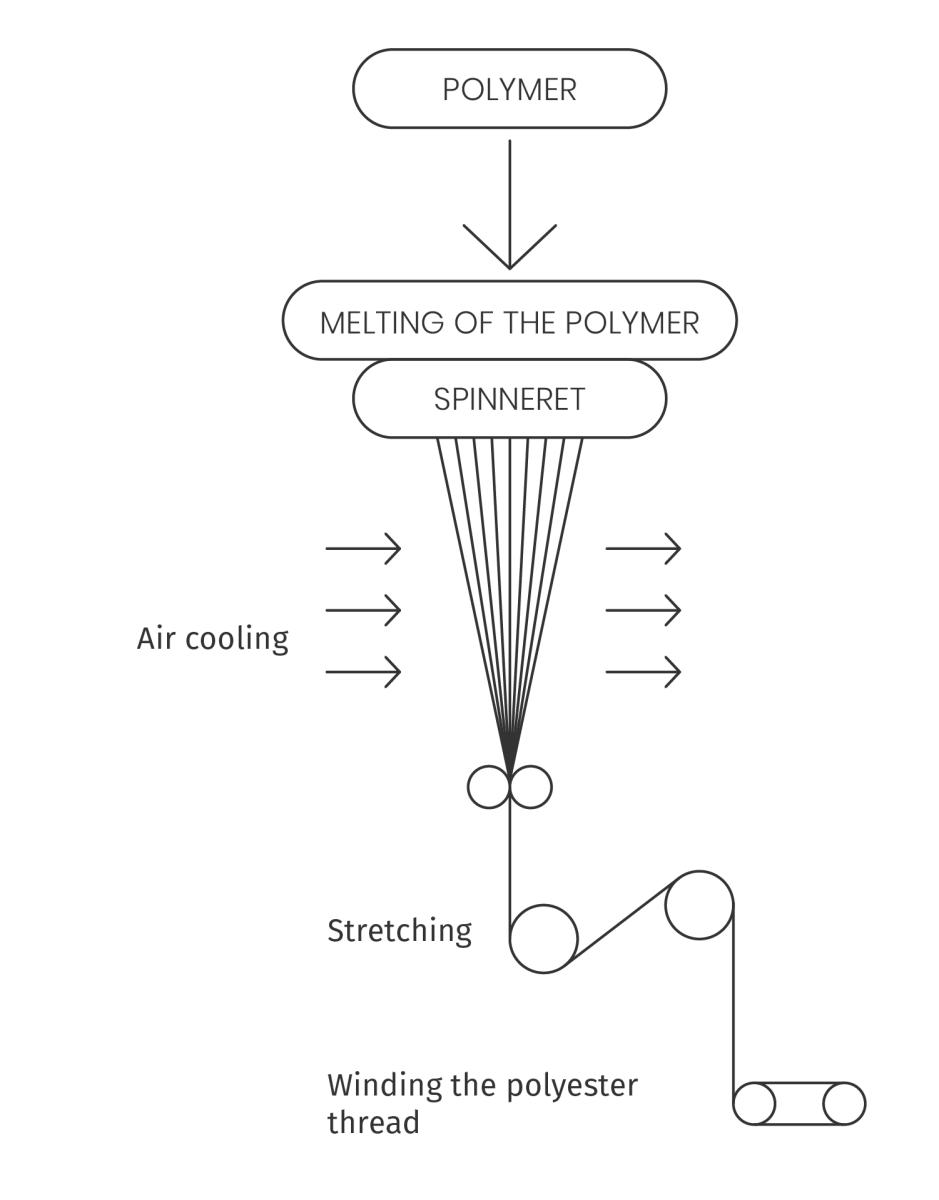

The raw material used to create polyester is oil. To transform polyester into polyester thread:

- The oil is polymerised, it's the chemical reaction which permits a polymer in the form of pellets to be obtained.

- The pellets are melted down then extruded through a die to give the polymer the form of a thread.

- Threads are then cooled and stretched before being wound around a bobbin. Polyester can then be used to make fabrics or pullovers.

Disclamer : As in all eco-design approaches, before choosing a material, it is essential to analyze the environmental impact of the entire life cycle of a product and to compare different scenarios in order to identify which one is the most beneficial for the environment.

There is no ideal material, it is necessary to choose a material according to the environmental attributes that we want to give in our product.

Polyester recycled from used textiles

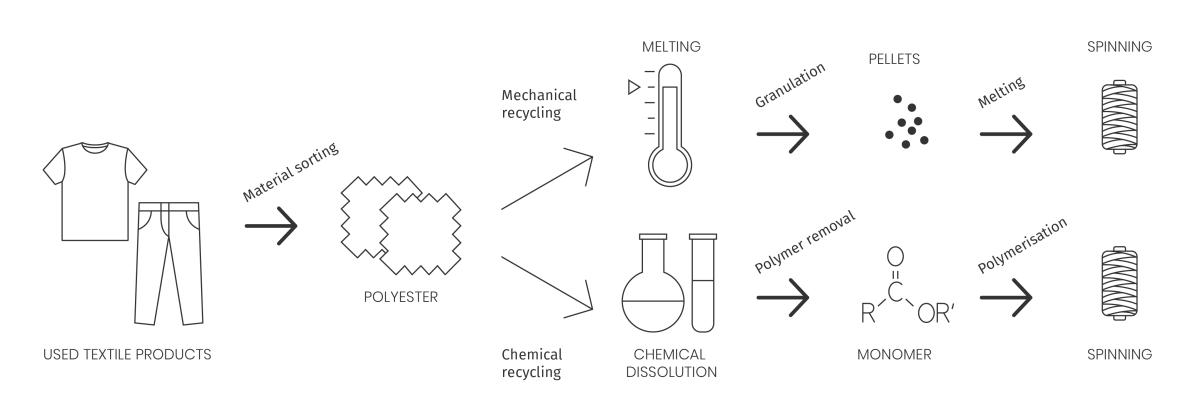

Polyester can be recycled from used clothing (known as post-consumer) or from production off-cuts (known as pre-consumer). Polyester can be recycled both mechanically and chemically. In addition to being used to recreate thread, recycled polyester has numerous outlets: plastics processing, unwoven fabrics or fuels.

Mechanical polyester recycling: to create a polyester thread via a mechanical recycling process, materials must firstly undergo a melting stage to return the polymer to a liquid state. Granulation follows in order to form pellets. Once the polyester is returned to pellet state, it can undergo a classic spinning process.

Chemical polyester recycling: :to create a polyester thread via a chemical recycling process, materials must firstly undergo chemical dissolution to regenerate fibres. Fibres are depolymerised to bring them back to a monomer state. Following this treatment, the polyester can undergo a classic spinning process.

Polyester recycled from plastic bottles

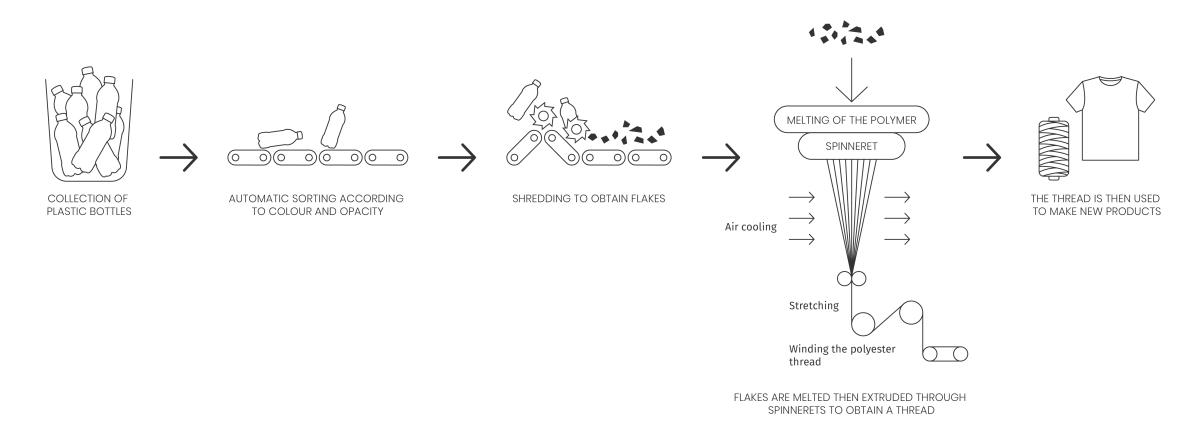

Products from industries other than the textile industry, such as the PET (Polyethylene Terephthalate) plastic bottles, can be used to create a recycled polyester thread. The product most often made from recycled PET bottles is the fleece jacket. 27 PET bottles are necessary to make one fleece jacket.

PET bottles are collected then baled. They are sorted according to colour and opacity (only transparent, uncoloured bottles are recycled). The tops are separated from the bottle as the plastic is different. The bottles are then ground to obtain flakes.

These flakes are cleaned and undergo a thermal treatment process to take on the form of pellets. The pellets are melted to obtain a paste which is extruded in the form of a filament after passing through a die (plates with small holes). The filaments are coated then stretched to form a thread. The process permits a RPET thread to be obtained. (Recycled Polyethylene Terephthalate).