Can you briefly describe your approach?

Eight years ago, I decided to create the company Insoft based on three major values: innovation, proximity and respect for the environment.

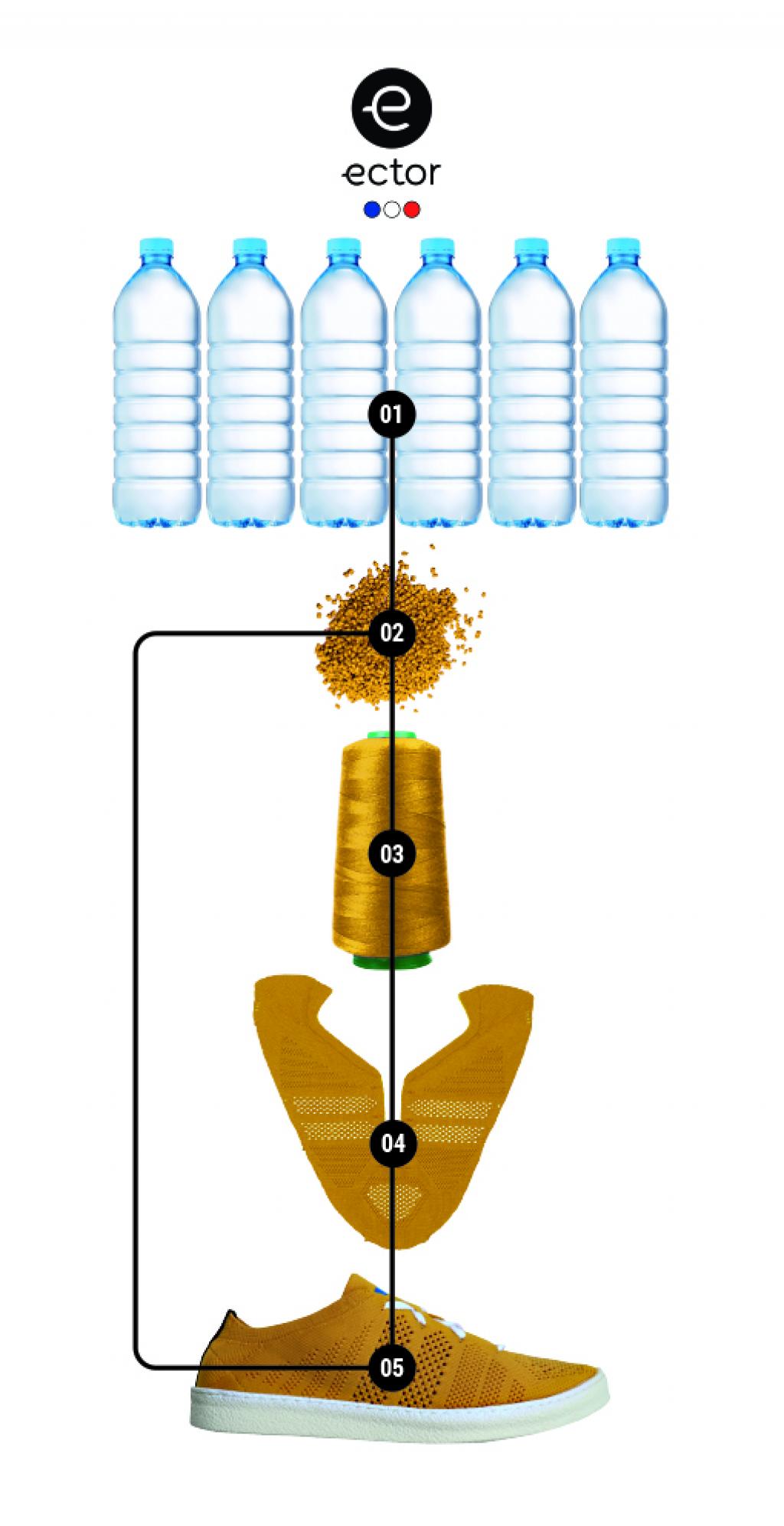

It’s with this in mind that we developed “ector” the first footwear knitted using recycled polyester made from PET bottles and which can be recycled at the end of its life.

We chose knitting because this technique allows material waste to be reduced. Its is both ecological and economical because the simplified process and the savings made in the use of materials enable production costs to be reduced thereby allowing manufacturing to take place in France, whilst maintaining an affordable price (between €90 and €125).

What working method did you use? What were its different stages?

Initially we wanted to use natural wool yarn or natural cotton thread for the shoe upper. However, we realised that if we wanted a fabric that could be 100% recycled we needed continual thread ant not one that is made from a group of fibres as are cotton thread and wool yarn.

Indeed, during mechanical recycling, natural fibres are broken down during fibre removal at the end of the product’s service life but they aren’t long enough to remake good quality thread. It is also necessary to add a virgin fibre to guarantee the technical properties of cotton or wool. So, knitting ector footwear required stringent specifications. We therefore opted for affordable 100% recycled polyester thread that can be recycled and that adapts well to knitting machines.

To make a 100% circular product, suitable industrial processes are required as well as materials that are compatible with such a process.

To come full circle, we will take back end-of-life ector footwear through a collection and recycling campaign. Soon we’re going to install permanent collection terminals.

So, we’re creating these products as well as managing the end of their service life.

Did you encounter any obstacles? And if so, which ones?

When producing in a circular economy there must be no compromises in regards to requirements in the process, the selection of materials, the design and creation: the product must integrate all environmental requirements whilst remaining attractive. For example, the request for a single material is difficult to overcome during the creation phase.

There are also manufacturing restrictions: today we make nearly all of our ector footwear in France but the yarn comes from Italy because for the moment in France there aren’t any spinners that enable yarn to be made from recycled polyester.

In addition, it’s difficult to combine budgetary, marketing and sales demands that are sometimes short-term, with projects requiring more than six months brainstorming work and which are, by definition, long-term. The pace the development of our collections is thus different to that of rest of the market: we renew the colour of our existing models every year and bring out a new model of trainer every two years.

We’re the first in France to use knitting technology for shoe uppers. We’re a small business but luckily organisations such as Eco TLC are providing assistance and support in this pioneering process.

What were the levers for success?

Local production and the proximity of our suppliers are genuine levers for success because we can easily go to meet them.

Furthermore, the increasing environmental awareness that we have seen over the last 3 years is also helping our business: we’re in keeping with the times. Our teams are proud to be pioneers in this area and to lead the way. We’re proving that it’s possible to combine fashion and the circular economy and we’re being recognised by big names in fashion, as our co-branding, started in January 2020 with Agnès b, demonstrates.

Are you looking at ways to improve?

We want to continue improving: we recently relocated our sole production activity, previously based in Portugal, to France. We’re also developing new ector models (other trainers and slip-on models).

We made the choice to invest in production tools and modern solutions, lower manufacturing costs, in order to continue to produce in France. By investing in industrial innovation, we can find solutions to transform our economic models.

Thank you Patrick Mainguené, CEO, Insoft.

Contact : contact@in-soft.fr