The WG is headed by Toni Gallone, ex Technical Director at Renault and CEO of ICRM (Impulse Circula’r Raw Materials), a consulting firm for academic bodies, companies and major clients. His role in the WG is to define the manufacturing process, the industrial scheme and business model.

The working areas of the Nonwovens Working Group

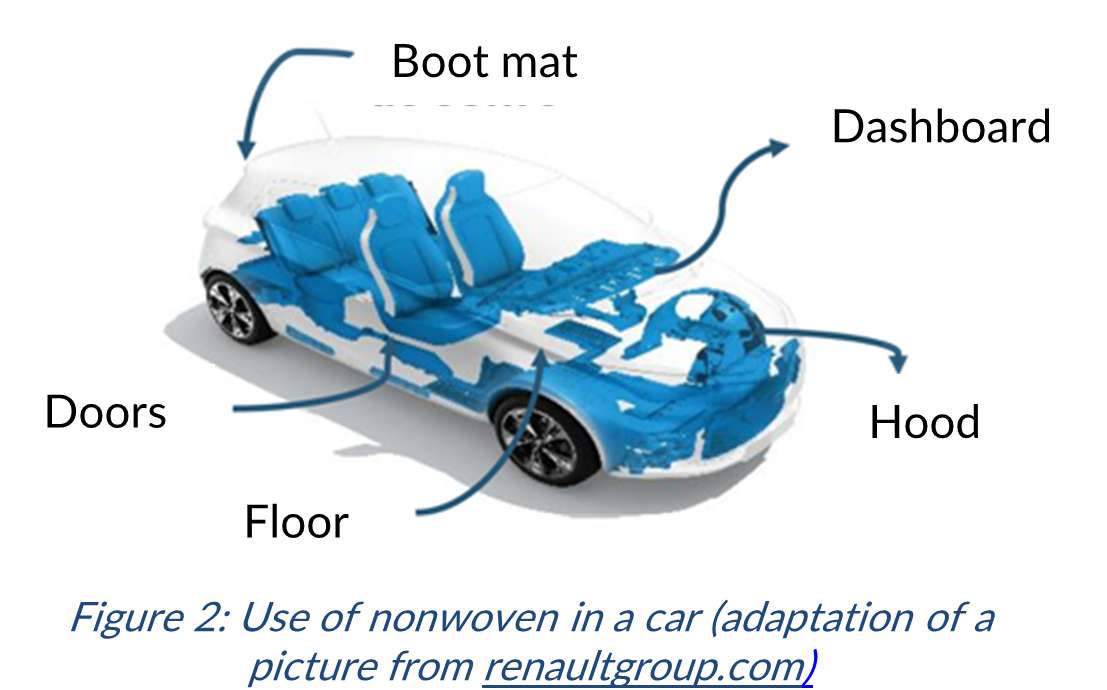

A nonwoven comprises a layer of randomly or directionally aligned fibres, bound by friction and/or cohesion and/or adhesion (Figure 1). Nonwovens are notably used as acoustic absorbers in the Transport sector (automotive, rail, etc.). In the automotive sector, they can be found in a car’s boot, doors, floors, hood and dashboard (Figure 2).

Some manufacturers (Volvo, Renault and PSA) have made some undertakings to use more recycled materials in newly designed vehicles. The expected features of products manufactured with these materials are: acoustic performance, lightness, and recycled and recyclable content. However, the development of these eco-designed products has been hampered by higher costs and potential risks linked with using recycled materials. The Nonwovens WG has therefore been particularly vigilant on these two latter points.

Four key stages have been identified and implemented by the Nonwomens GT:

-

Identification of feedstock sources, stakeholders and of transformation processes ;

-

Pre-feasibility tests and characterisation of the resulting products ;

-

Reproducibility test, development of a prototype & VALP (validation plan) of the eco-designed product ;

-

Technical-economic assessment and evaluation of the industrial scheme.

Creating a range of samples for the WG's automotive suppliers

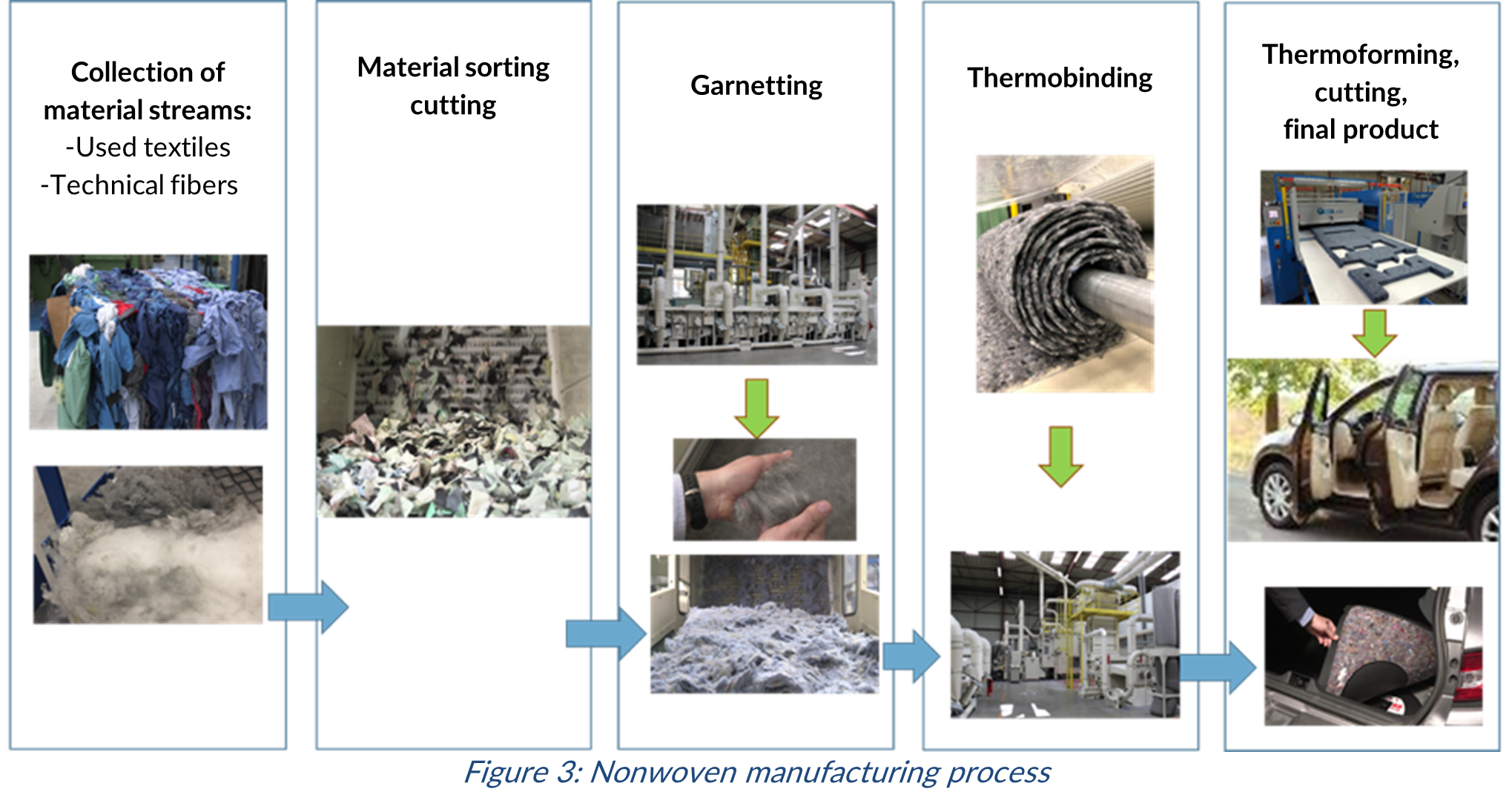

In order to study the project’s feasibility, a range of nonwoven samples was developed at the CETI (European Innovative Textiles Centre). The manufacturing process is shown in Figure 3. Used non-reusable clothing and household linen are collected, sorted per fibre type, then cut up into rags before garnetting. Once garnetted, fibres are thermobound, i.e. heated with hot melt additives, in this case thermobinding fibres. The nonwoven material is thereby obtained and transformed into a finished product: cuttings, addition of covering layers and finalisation of the thermoforming process.

Ten samples were made from used non-reusable textiles, with addition of technical fibres (rPET and PA) and BiCo thermobinding fibres. Samples varied in terms of thickness, surface mass and fibre proportions.

Sample characterisation

Nonwovens made from used non-reusable textiles must have the following properties in order to be introduced into the transport market:

-

Acoustic performance, the most important property. Performance must be particularly high in low frequencies (around 800-1000 Hz) in addition to high frequencies. This is particularly important in electric vehicles including exterior parts;

-

Being lightweight;

-

Having recycled and recyclable content;

-

Heat resistance and combustibility, in particular for motor compartment parts that must meet stricter specifications than those for exterior parts;

-

Other requirements in the car manufacturers’ validation plans (mould resistance, etc.).

To be competitive in the car industry, weight savings are essential. However, a nonwoven that is too light would not satisfactorily fulfil its acoustic absorption function. The technical challenge is to find the compromise between the right quantity of raw materials used for the product and its acoustic properties, knowing that it is possible to play with the ratios of the three fibre types (recycled, technical and thermobinding fibres) in the mix when manufacturing the nonwoven samples.

The following paragraphs describe the different tests carried out on the nonwoven samples by the CTTM Laboratory (Le Mans Technical and Transfer Centre).

1. Acoustic absorption measurements in Alpha Cabin

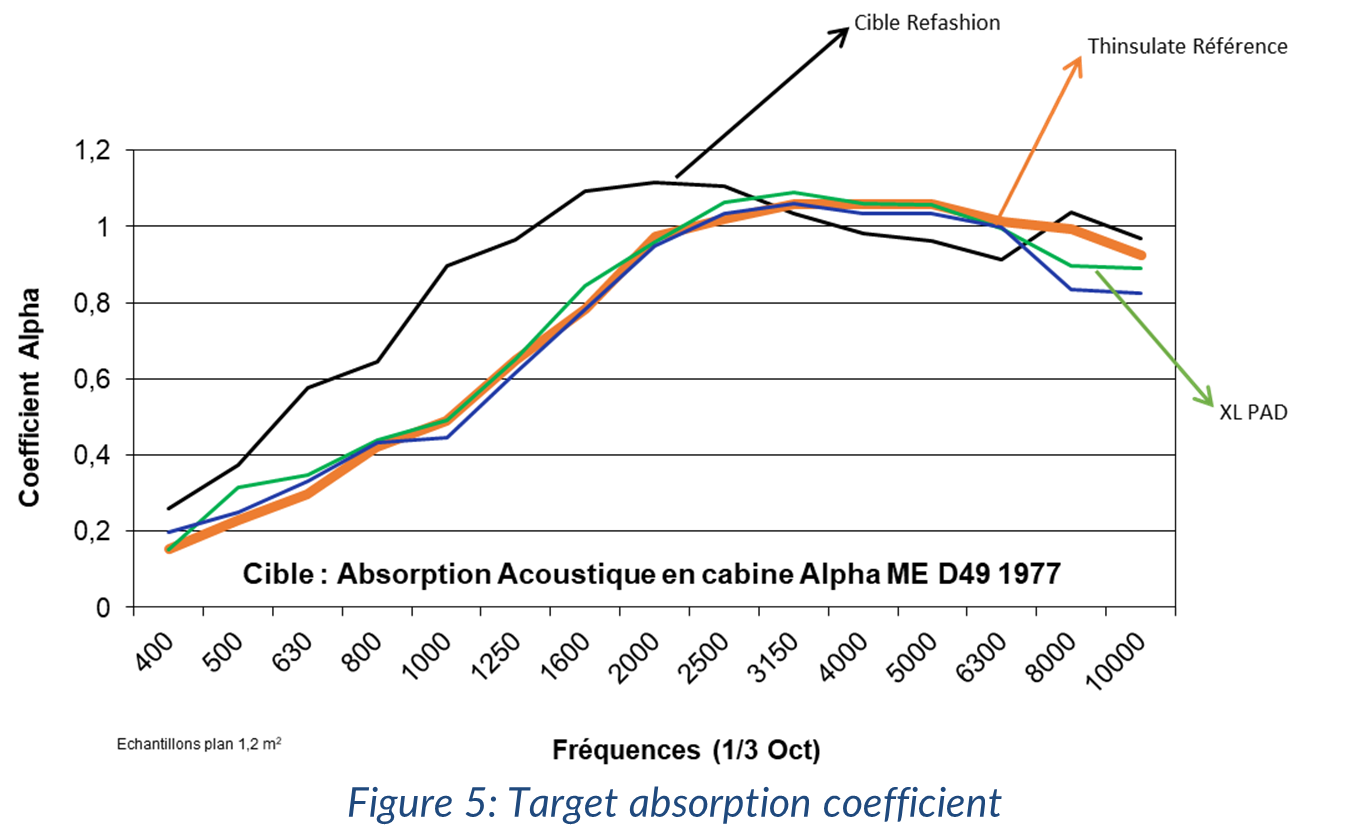

Three nonwoven samples selected by the WG were tested in an Alpha reverberation cabin following a certified manufacturer procedure. The Alpha cabin enables the acoustic absorption coefficient of automotive equipment to be measured (Figure 4). The WG is targeting an absorption value that is particularly efficient for the first third of octaves (Figure 5).

First results have been very satisfactory in regards to expectations.

Areas of improvement in acoustic performance:

In order to improve the acoustic performance in relation to “acoustic classifications” as defined by the manufacturers, resistive felts made from various compositions were added onto the nonwovens so to improve the final product.

Bonding tests were carried out with three felts to evaluate potential delamination and to obtain the best “acoustic performance / weight / bonding” compromise whilst paying attention to the final product’s cost.

Experiments show that the addition of felts enable the absorption levels of low frequencies to be improved (500 to 800 Hz), allowing the three samples to reach the A and B acoustic classifications. However, the cost of these felts is non-negligible, making these nonwoven products a “premium” option.

2. Measuring mechanical / physical properties

In parallel, physical parameters (porosity, resistivity, tortuosity, viscous and thermal length characteristic) were measured and recorded for the three selected samples.

The values obtained were integrated in a simulation tool in order to model the theoretical design and composition of an optimal final product, with or without a resistive felt.

The 3 highly acoustic performant nonwoven samples, integrating up to 70% of recycled textiles, have been validated by 2 automotive suppliers.

Validation plan for eco-designed products

Eco-designed nonwovens must also meet a validation plan (VALP) defined by manufacturers, such as Stellantis and Renault.

Validation methods for “finished products” (thermoformed or other) vary depending on the manufacturer and some sought specificities may also include:

-

VOC / Odours emissions;

-

Fire-proofing treatment;

-

Antibacterial / anti-mould treatment.

Given that the manufacturers communication on the environmental impact of their final marketed products, performing an LCA on the nonwomen material is also required.

Using recycled nonwomens enables the environmental footprint to be reduced:

-

during a vehicle's use due to the fact that it contributes in reducing its weight (up to 50% in mass);

-

during the production of nonwomens by using recycled resources thereby avoiding the use of virgin fibres (natural and/ or petrochemical).

-

de la production du non-tissé grâce à l'utilisation de ressources recyclées évitant ainsi l'utilisation de fibres vierges (d'origine naturelle et/ ou pétrochimique).

Stakeholders in the value chain

The WG’s last step is to associate the different industrial stakeholders in order to confirm commitments and get to a credible “costs” chain. To do this, several consultation rounds were conducted and different scenarios for vehicle launches were presented to identify needs (feedstock sources to prepare and process, turnover to reach, etc.). An invitation to tender was launched at the beginning of 2022 to identify and select stakeholders for developing an industrial scheme.

Technical-economic assessment

Technical and logistical methods in the recycling chain raise challenges. Several parameters must be considered such as the heterogeneity of post-consumer feedstock, the length of the resulting recycled fibres, the presence of potential contaminants, the costs associated to bulking (logistical approach and distribution), etc. It is therefore essential to re-think the entire value chain in order to encourage the use of recycled materials.

A preliminary market study was carried out to define:

-

The commitment and the quality assurance of sorting operators for the material sorting and pre-processing of used non-reusable textiles. These operations allow to provide a qualitative post-consumer feedstock to materials processors;

-

Logistics with the location of bulking platforms;

-

The selection of industrial stakeholders.

The Refashion Material Sorting and Preparation (MSP) Committee

In order to rally sorting operators for the preparation of suited materials for industrial materials processors, Refashion launched the Material Sorting and Preparation Committee at the beginning of 2022. Its aim is to determine viable recycling processes and calculate the costs generated by the additional material sorting and preparation of used non-reusable textiles.

Two technical specifications were provided to sorting operators within the MSP Committee in order to validate the Nonwovens WG’s preliminary study. Two nonwoven pre-production runs have been carried out at the CETI with feedstock prepared by some sorting operators part of the Committee. The nonwoven samples, produced on a larger scale before the industrialisation of the process, were tested again at the CTTM which confirmed their high acoustic performance.

Towards industrialisation

The Transport Nonwovens WG enabled to create a technical nonwoven from post-consumer non-reusable textiles, meeting the requirements of automotive suppliers.

With the aim of industrially producing this eco-designed nonwoven, several aspects are studied in order to validate the industrial value chain :

-

Different solutions proposed for used textile materials sorting and preparation, and their related costs (in a second phase, the development of automated sorting and pre-processing of used clothing will enable significant financial savings);

-

Bulking of prepared feedstock.

Different scenarios are being evaluated in order to ensure a competitive and viable solution for all involved stakeholders.