Can you briefly describe your approach?

The 1083 brand was created in 2013. We wanted to relocate our jeans manufacturing operation which is one of the most polluting products in fashion industry. Our brand aims at providing solutions to three major stakes.

- Relocate manufacturing to France;

- Relocate retail to town centres;

- Develop sectors and products with a reduced environmental impact.

What working method did you use? What were the different stages?

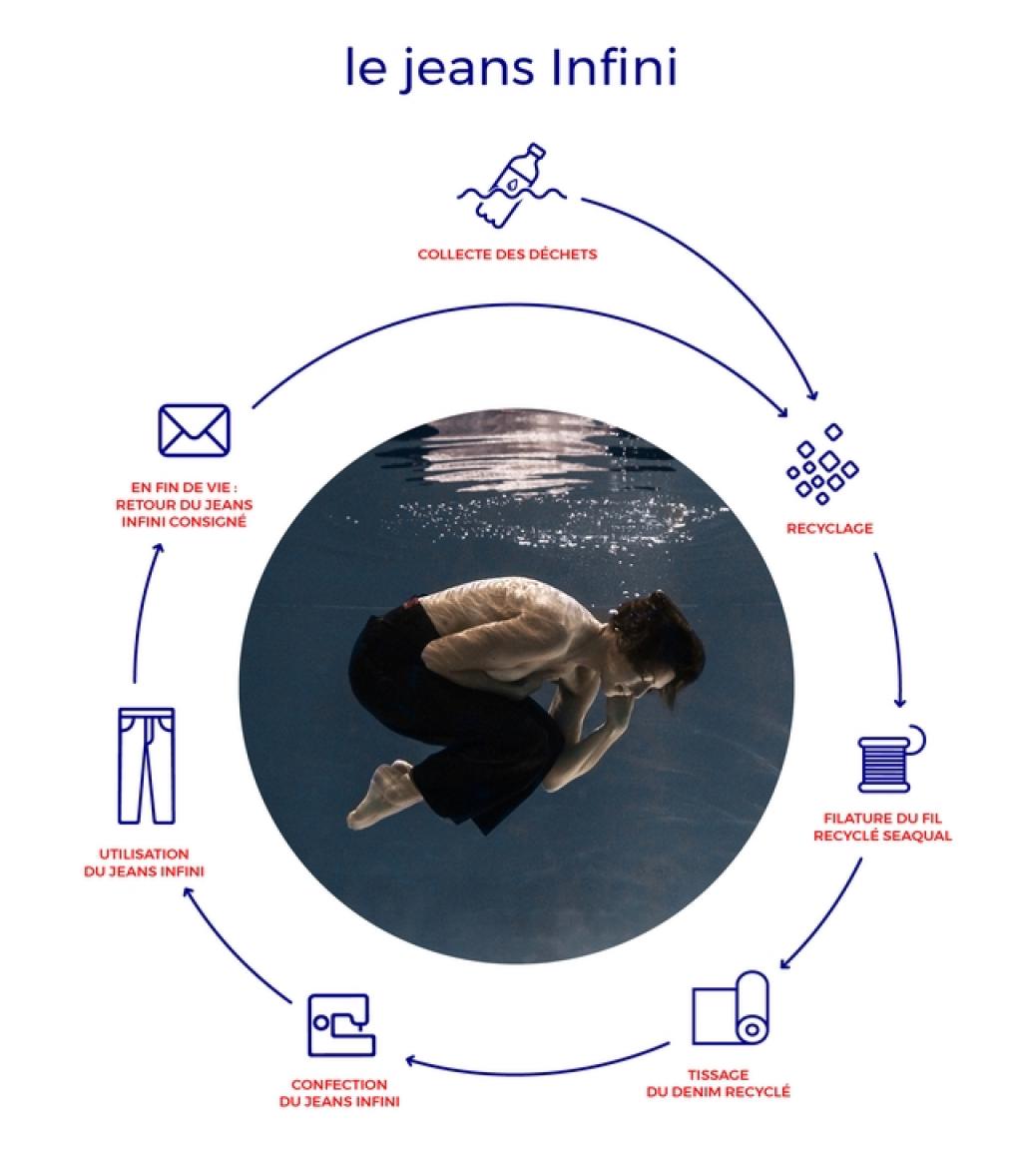

The Infini range was developed because we wanted to produce the very first range of jeans while thinking about end of life from the conception step. Classic jeans are complex products to recycle because they comprise hard points and a multitude of materials: cotton, elastane, etc. To create a pair of jeans that can be efficiently recycled we decided that our Infini jeans would contain a single material, 100% polyester.

Developing such a range required three years of research and development in order to bring about a revolutionary change: a pair of jeans manufactured entirely from recycled materials, returnable so we can have an hand on the recyclability. We carried out several adjustments particularly in terms of eco-design: the cut, the pockets, hard points, etc. were redesigned. Our thread is manufactured using plastic waste collected from the ocean, by the company Antex, in Spain.

Even if our skills have become very much in-house, the work was very much collaborative: our partners helped a great deal in regards to the spinning and weaving of our jeans. We particularly work with two long-standing textile manufacturers in the Loire and Vosges regions. Our suppliers rallied around us in order to provide materials with low environmental impact. We are also trying to share our experience with other brands as much as possible because this is how we can develop and strengthen the French denim sector.

We launched the 2016 Infini range with crowd-funding from the Ulule platform: we received 850 pre-orders. The first operation was a success: we sold more than 1,000 pairs of jeans. We managed to create a very strong community around 1083 that has supported and encouraged our new projects.

We’d like to track our jeans right to the end of their life. So in keeping with a rationale of producer responsibility, we’re managing the end of their life: we’re reimbursing 20 euros for every pair of jeans returned to us by buyers when they’ve reached the end of their service life and we undertake to create a new pair of jeans from the used pair. This is the advantage of using polyester: the fibre is not or few altered during recycling.

Did you encounter any obstacles? And if so, which ones?

Eco-design within the fashion industry is both an industrial and technical challenge as well as one in terms of aesthetics of design. Aspects such as single material, material sourcing, hard points and pockets pose problems that require a substantial amount of research and development work to be undertaken upstream to the projects.

The Infini range was an ambitious and demanding project right from the start. Finding the appropriate arguments for our partners and suppliers was necessary in order to present a well-thought through, cost-effective and sustainable project.

What were the levers for success?

Our community constitutes the first lever of success for the Infini range. Thanks to its rallying abilities, it makes it possible for pioneering projects to be undertaken. We unified this community thanks to the Ulule platform: it is has become our brand’s ambassador. We communicate directly and transparently with the community, particularly via social networks. We speak about our everyday activities and are open about our failures. We have a very high participation rate on social networks, whilst spending very little of our budget on communications (sponsorship and advertising).

We’ve also benefited from media attention and a huge interest from customers in our jeans, which gave good visibility to our brand.

Finally, we’re a small, reactive and flexible team: this enables us to respond and work quickly.

Are you looking at ways to improve?

One of our largest areas of work is the Moncoton project: we want to create a new type of cotton thread for textiles in France made from used clothes, in particular jeans and underwear.

The Infini range has allowed us to affirm our ambition for a circular economy at 1083. Ultimately we wish to extend this to all our products, particularly through the Moncoton project. We would like to rethink all the stages of textile production in France little by little and bring production and clothes consumption closer.

It is intended that the Infini range be developed beyond our brand. We are working with other companies such as Hopaal on industrial overalls and the Slip Français on "Infini" swimwear, recycled and returnable.

Finally, our last challenge concerns the footwear that we’re manufacturing. We’re working with various companies in order to have the higher potential care rate for recycling for our footwear range.

Thank you Sébastien ROCHIER, Brand Division Manager, 1083.