How did you get the idea to improve end of life footwear?

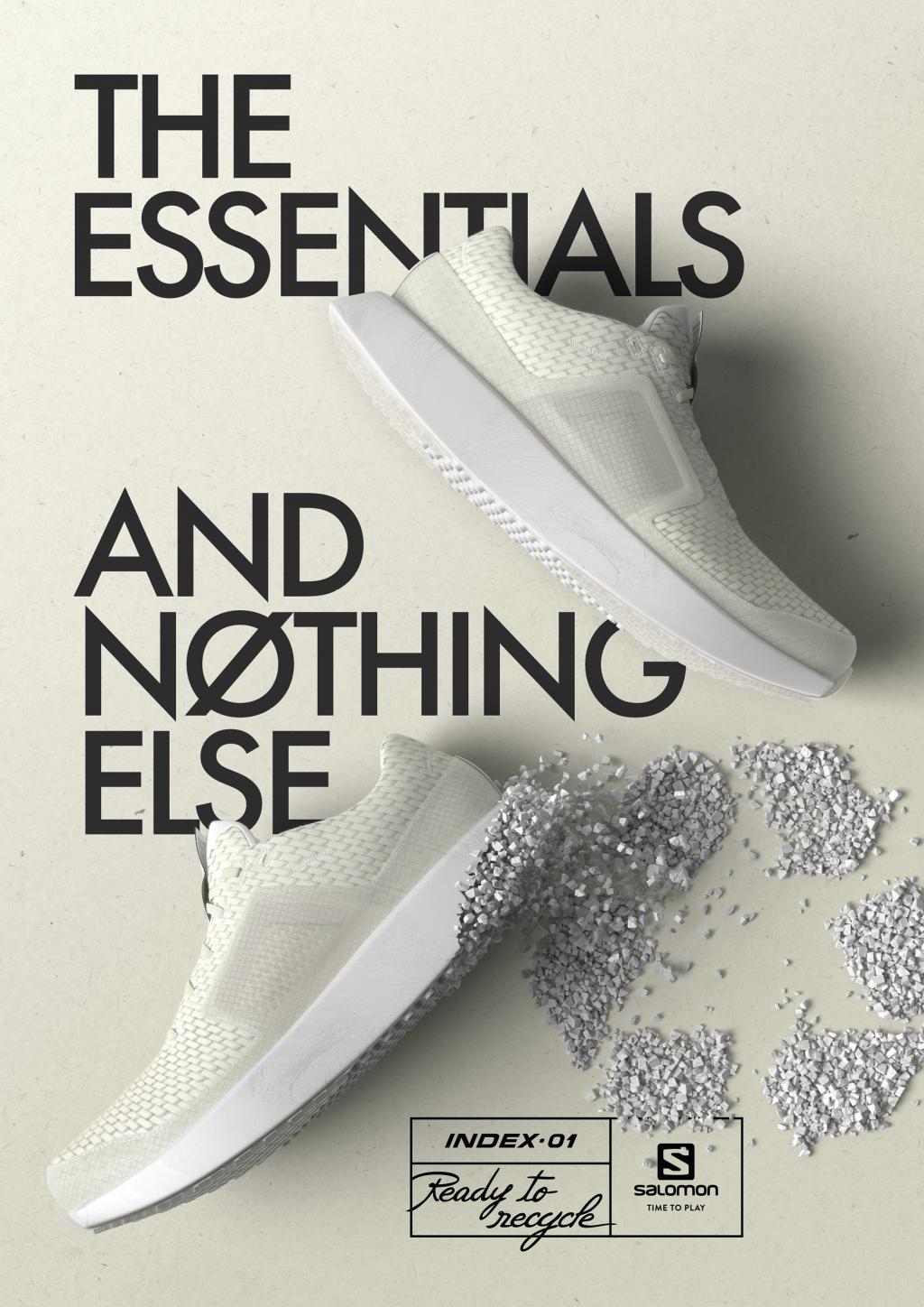

Footwear is the largest business within Salomon today. As we wanted to improve our efforts on the end of service life of our products, we needed to work the footwear sector. When we started to analyse in order to find solutions, we were initially shocked by how many different materials were found in sport shoes. There’s at least 6 different categories of materials. Rubber for ground contact, EVA (ethylene vinyl acetate) foam for comfort and for the shoe upper, polyamides, polyester, TPU (thermoplastic polyurethane), PU (polyurethane), various foams etc. Of course, the ideal would have been to manufacture a sport’s shoe from a single material. But it is complicated to find a single material able to fulfill all functionalities (comfort, grip, etc.) required for footwear. We said to ourselves that we were going to develop footwear made from polyester and TPU, two materials that can be recycled in their sector, source and assemble them in such way that they can be easily separated in order to recover them better when the product has reached its end of service life.

Why are polyester and TPU (thermoplastic polyurethane) interesting materials?

Both have their recycling process. Our recycled polyester comes from plastic bottles. As for TPU, this is a plastic that can be heated like plasticine to reuse it. For example, we are going to use it for manufacturing ski boots. This can allow us to reduce our consumption in virgin raw materials.

Can you briefly describe your process?

TPU is sold in the form of granules intended to be introduced into raw materials by suppliers. We introduce them to manufacture comfort-providing soles for and soles with gripping properties. Our subcontractors produce a fine film or filament from these granules. The film can be “directly” used but the filament still needs to undergo several operations. They are them assembled and twisted to make yarn that will be sent to a company who will make it into textile. It’s at this moment that we, Salomon, buy it. As regards polyester, it follows the same pathway as TPU textile (granules, filament extrusion, assembly, twisting, weaving or kitting). We use virgin raw polyester, produced from oil by a chemical company, and recycled polyester produced by a plastic bottle recycler. We are working on the proportion of these two categories of materials according to the desired mechanical properties and costing objectives. If certain polyester granules are occasionally produced in Europe or North America, most of it comes from Asia. 90% of the world’s footwear is manufactured there too. We are RCS 100 (Recycled Claim Standard) and GRS (Global Recycled Standard) certified for these recycled materials and are in the progress of certifying our factories with the Fair Labor Association. We should obtain this by 2023. We have a Restricted Substances List (RSL) too, a reference system that guarantees that our suppliers do not use certain chemicals that are a harmful to health or to the environment.

What is the environmental impact of these Index.0.1 trainers?

The life cycle analysis of this footwear reveals that the mere fact of having simplified footwear design, has enabled its impact to be reduced for 6 evaluated criteria: climate change, acidification, eutrophication, use of resources, depletion of non-renewable energy sources and depletion of the ozone layer. Its impact on climate change has been reduced by 24% compare to standard footwear. If customers send the trainers back for recycling, this reduction stands at 38%, taking into account cleaning, shredding, and the bonus for recycling by reusing materials.

Is the Index.01 trainer designed differently in order to last longer?

It was out of the question to alter the durability of the product over time. This trainer’s life span is at least the same as that of our standard running shoes.

Are there technical limits?

The Index.01 trainer is the equivalent of a traditional product in terms of bounciness and fatigue over temps. But TPU foam isn’t as light as the others. The Index.01 weighs 290g compared to 170-200g for running shoes. The sole hasn’t the same level of grip as rubber. However it is largely sufficient for running on roads. It’s therefore more suitable for training than for competitions.

How do you plan on recycling the Index.01?

The aim was to keep each material as pure as possible in order to make it easier to recycle them. We have therefore very distinctively isolated and placed the TPU and the polyester in the trainer, making these easier to separate and sort. All of the underfoot is in TPU and the upper part of the trainer is in polyester and can be separated using scissors. We have made an effort not to integrate elastane into the materials in order to make their recycling easier. Furthermore, they are assembled mainly by sewing and we have replaced solvent-based glues with water-based ones, which we feel is healthier. The only drawback is the comfort-providing sole, which cannot be recycled, but is made from 100% recycled material.

How have you organised the collection and recovery of these used trainers?

We didn’t think that leaving such a product in the open seemed a very consistent approach because no doubt it wouldn’t have been recycled. So we placed a QR code and a website link inside the shoe box. Customers can thereby register themselves on our website. If customers do this, they receive a message 9 months later, reminding them that their product can be recycled and that if it’s worn out, they can download a free return voucher and return it via our after-sales service.

For the moment we’ve limited this product’s sale and distribution to three platforms in Europe, the US and Canada, and one in China. Each product to be recycled is returned to the continent’s original platform, where it’s cleaned and disassembled. In Europe, TPU is recycled in our factories in Romania, which manufactures mountain shoes. We work with European partners to have an efficient recycling branch for polyester.

How is the product viewed by customers?

We’re reach out to our customers’ good citizen side. They’re sympathetic to the approach, but changing mentality is difficult to do. For example, we haven’t provided any incentive for returning the trainers. However, we’ve seen that registration on the website just after purchasing, enabling to return the product when required, hasn’t reached the expected level.

What’s your next step?

We’re working on making the trainer lighter because its weight may be a criteria for not buying it. We’re also trying to reduce its price in order to make it more affordable to more customers, and to widen distribution. Lastly, we are looking to simplify its disassembly. For the moment this can be done using scissors, but this won’t be sustainable for larger production levels. This is a test year, allowing us to learn. We’re working on improving the product and on offering others for the 2022 and 2023 collections.

Thank you Olivier MOUZIN, Sustainable Footwear Manager at Salomon .